| Particulars |

Advantages to |

| Assembler User |

End User |

| Direct |

Indirect |

|

Highest clamping range for emergency use at alternative smaller size applications and thus reduces inventory. |

|

|

|

|

| Wider tolerance allowable on hose thickness and insert tube reduces expenses of mating parts. |

|

|

|

|

Vibration-proof quality by Worm Drive Principle avoids risk of leakage and Warrantee claims & gains goodwill. |

|

|

|

|

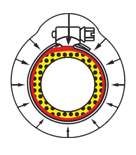

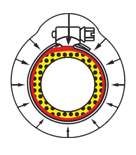

| High clamping pressure with low tightening torque provides convenience at Assembly. |

|

|

|

|

High band flexibility adjusts itself to suit the shape of mounting hose & its deflected inserts. |

|

|

|

|

| Corrosion resistance by use of S. S. avoids periodic repurchases. |

|

|

|

| Omission/minimum use of Zinc Plating helps to follow Environment Protection Norms. |

|

|

|

| Provision of high safe torque strength values assures safety against dangerous slippage causing total loss of clamp, coolant, engine performance and thus avoids warrantee claims and adds to goodwill. |

|

|

|

|

Uniform radial clamping pressure all over the hose engagement area enhances leak - proof quality and hose life. |

|

|

|

|

| Withstands climatic fluctuations from hot to below 0 c with leak - proofness. (Ref : Type JW 7 D) |

|

|

|

| Saves non-clamp expenses of non-standard crimpling installation tools required for certain designs. Avoids problems of non-availability of such tools at fieldwork. |

|

|

|

|

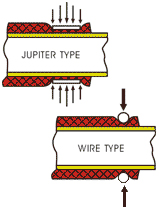

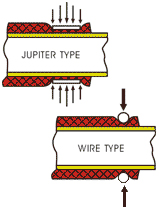

Uniformly distributed pressure by Jupiter on wider hose area by strip type band increases hose life unlike clamping by wires, which penetrates the same and reduces hose life. The indirect benefit of strip band is thus transferred to hose. This is very true for soft surfaces of precious Silicon hoses or costly coolant connections. |

|

|

|

|

| Longest life of Jupiter avoids repeated inflationary purchase cost with O.H. suffered by the end-user caused by short life clamps. |

|

|

|